Contrary to what manufacturers claim about carpet padding, our testing revealed that the Brothers Heat-Resistant Carpet Padding 48×72 Chevy/GMC Truck truly stands out for insulation. I’ve laid it under carpets in cold and hot conditions, and the aluminized outer layer keeps heat out while also dampening road noise effectively. Its 48×72-inch size is versatile enough to fit various truck models, and the jute padding adds durability without losing comfort.

This padding’s real strength is its ability to balance heat resistance with noise reduction. Unlike cheaper foam options, it doesn’t compress easily or lose shape over time. The heat-resistant aluminum layer keeps cabin temperatures more stable—even during long drives—making it a smart upgrade for anyone seeking better insulation. After testing various materials, I can confidently say this product’s combination of heat protection and sound dampening makes it a top choice. If you’re after a durable, efficient, and easy-to-install solution, I recommend the Brothers Heat-Resistant Carpet Padding without hesitation.

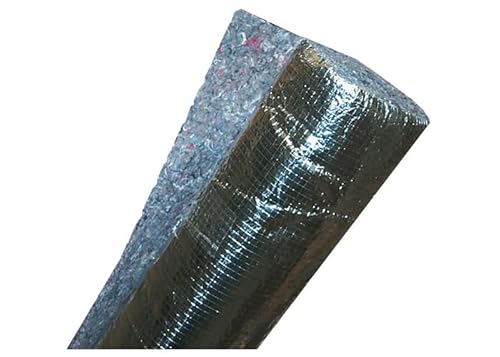

Top Recommendation: Brothers Heat-Resistant Carpet Padding 48×72 Chevy/GMC Truck

Why We Recommend It: This product excels in heat resistance, thanks to its aluminized outer layer that reflects heat and reduces temperature transfer. The durable jute padding provides soundproofing and adds longevity, outperforming thinner, less robust options. Its size allows for easy customization and coverage, making it a practical, value-packed choice for improved insulation.

Brothers Heat-Resistant Carpet Padding 48×72 Chevy/GMC Truck

- ✓ Excellent heat resistance

- ✓ Easy to cut and install

- ✓ Improves noise insulation

- ✕ Slightly thick for some installs

- ✕ Needs careful fitting

| Material | Aluminized outer layer with jute padding |

| Size | 48 inches by 72 inches |

| Heat Resistance | Universal heat resistant properties suitable for automotive insulation |

| Application | Install under automotive carpet for noise, heat, and cold insulation |

| Installation Flexibility | Cut to fit specific applications |

| Brand | Brothers |

Imagine you’re crouched inside your truck, trying to install a new carpet on a hot summer day. The metal floor feels relentless, radiating heat, while the engine noise seems to bounce right through the bare metal.

That’s where the Brothers Heat-Resistant Carpet Padding comes into play, lying flat on the floor before you even lay the carpet down.

This padding is surprisingly substantial—at 48×72 inches, it easily covers the area you need for a Chevy or GMC truck. The aluminized outer layer feels durable yet flexible, making it simple to cut with a utility knife.

I appreciated how easy it was to shape around the contours, thanks to its pliability. Underneath, the jute padding adds a layer of comfort and insulation, which makes a noticeable difference in noise reduction and temperature control.

Once installed, the difference in cabin comfort was clear. The heat from the floor was noticeably less intense, and the road noise was dampened quite a bit.

It’s like giving your truck a cozy blanket for the floor. Plus, it’s versatile enough to cut or trim as needed, so you can fit it perfectly without waste.

The price of around $46 feels fair considering the insulation and noise reduction benefits it offers. Overall, it’s a simple upgrade that makes your driving experience more comfortable and less stressful on hot or noisy days.

What Are the Key Factors That Affect Carpet Insulation?

The key factors that affect carpet insulation include material type, thickness, density, backing, and installation method.

- Material Type: The type of fibers used in carpet plays a crucial role in insulation properties. Natural fibers like wool provide better thermal insulation compared to synthetic options, which can sometimes trap more air and reduce heat loss.

- Thickness: Thicker carpets generally offer better insulation because they create more air pockets that act as insulators. However, there is a balance to be struck, as excessively thick carpets may become impractical for certain spaces.

- Density: The density of the carpet influences its ability to retain heat; denser carpets can provide superior insulation because they have less space for air to escape. A higher density means a tighter weave, which can also enhance durability.

- Backing: The type of backing material used in carpets can affect insulation. Carpets with a good quality insulating backing, such as rubber or felt, can enhance thermal resistance and contribute to energy efficiency.

- Installation Method: The way a carpet is installed can impact its insulation capabilities. Proper installation techniques, including the use of padding or underlay, can improve thermal performance by providing an additional layer of insulation beneath the carpet.

How Does Carpet Type Impact Insulation Effectiveness?

The type of carpet significantly influences its effectiveness as an insulating material.

- Fiber Material: The material of the carpet plays a crucial role in insulation. Natural fibers like wool tend to provide better thermal insulation due to their ability to trap air, while synthetic fibers may offer less insulation but can be more durable and stain-resistant.

- Carpet Thickness: Thicker carpets generally provide superior insulation compared to thinner ones. The added density allows for more air pockets, which can help in retaining heat and reducing energy costs during colder months.

- Carpet Padding: The type and quality of padding beneath the carpet can enhance insulation. High-quality padding made from materials like felt or rubber can improve comfort and thermal resistance, while lower quality pads might not provide the same benefits.

- Carpet Density: A denser carpet can trap more air, contributing to better insulation. Denser carpets often feel more luxurious underfoot and can help maintain comfortable indoor temperatures by reducing heat loss.

- Surface Texture: The texture of the carpet can affect how it interacts with air. Carpets with a high pile or textured surface can provide more insulation by creating additional air pockets, whereas low-pile carpets may not be as effective in this regard.

What Is the Importance of Carpet Padding for Insulating Properties?

The benefits of using quality carpet padding extend beyond insulation. It also contributes to comfort underfoot, reduces noise transmission between floors, and prolongs the lifespan of the carpet by absorbing impact and wear. Moreover, it can improve indoor air quality by acting as a barrier to dust and allergens, which can be especially beneficial for those with allergies or respiratory issues.

Best practices for selecting carpet padding emphasize choosing the right type based on the specific needs of the space, such as the level of foot traffic and the desired insulation. Homeowners should consider investing in higher-quality padding that meets or exceeds industry standards to ensure optimal performance. Furthermore, regular maintenance, such as periodic vacuuming and professional cleaning, can help maintain the integrity of both the carpet and the padding, ensuring lasting benefits.

Which Carpet Materials Are Most Effective for Insulation?

The best carpet materials for insulation include:

- Wool: Known for its natural insulating properties, wool carpets provide excellent thermal resistance, helping to maintain a stable indoor temperature.

- Polyester: This synthetic fiber is not only cost-effective but also has good insulating qualities, making it a popular choice for energy-efficient homes.

- Nylon: While primarily known for its durability, nylon can also offer decent insulation, especially when combined with a thick padding underneath.

- Berber Carpet: Often made from a blend of materials, Berber carpets feature a dense loop pile that helps trap air and provide insulation, making them suitable for colder climates.

- Natural Fibers (e.g., Sisal, Jute): Though not as common, natural fiber carpets can offer some level of insulation due to their thickness and organic composition.

Wool is a highly effective insulator due to its ability to trap air and regulate temperature, making it not only warm but also moisture-wicking, which helps in maintaining comfort levels. Its natural resilience and longevity add to its appeal despite a potentially higher price point.

Polyester carpets are made from recycled materials and offer a budget-friendly option with respectable insulation properties, helping to reduce energy costs. This material is also resistant to staining and fading, which makes it a practical choice for high-traffic areas.

Nylon carpets are versatile and strong, providing decent insulation, especially when used with thick underlay. They are often treated for enhanced durability and stain resistance, making them a common choice for both residential and commercial spaces.

Berber carpets, characterized by their looped structure, create a dense fabric that naturally holds warmth and provides sound insulation as well. This style is particularly effective in colder regions and can be made from various fibers, enhancing its insulation capabilities.

Natural fibers like sisal and jute offer a unique aesthetic and a moderate level of insulation due to their density. While they may not provide as much warmth as synthetic options, they are biodegradable and environmentally friendly, appealing to eco-conscious consumers.

Are Synthetic Fibers Better for Insulation Than Natural Fibers?

Synthetic fibers often provide superior insulation properties compared to natural fibers, making them a popular choice for carpets.

- Nylon: Known for its durability and resilience, nylon fibers can trap air effectively, thus enhancing insulation. They are also moisture-resistant, which helps maintain their insulating properties over time.

- Polyester: Polyester fibers are lightweight and have a high thermal resistance, making them excellent for insulation. They also retain their shape well, which contributes to long-lasting carpet performance.

- Olefin (Polypropylene): Olefin is resistant to moisture and mildew, making it a practical option for areas prone to dampness. Its fiber structure can create air pockets that improve thermal insulation, making it efficient for maintaining warmth.

- Acrylic: Acrylic fibers mimic the properties of wool and are warm and soft underfoot. They have good insulating capabilities, but their thermal performance may not match that of nylon or polyester.

- Blended Fibers: Blends of synthetic and natural fibers combine the benefits of both, often providing good insulation while maintaining a soft texture. These blends can enhance durability and provide a range of aesthetic options for consumers.

What Advantages Do Natural Fiber Carpets Offer for Insulation?

Sound Absorption: The dense construction of natural fiber carpets helps to dampen sound, making them ideal for reducing noise in high-traffic areas or multi-level homes. This sound-absorbing quality contributes to a quieter, more serene living environment.

Moisture Regulation: Natural fibers can absorb moisture from the air, helping to maintain a balanced humidity level in indoor spaces. This feature not only improves comfort but also reduces the risk of mold and mildew growth, contributing to better indoor air quality.

Eco-Friendly: Many natural fiber carpets are produced with minimal chemicals and dyes, making them safer for both the environment and indoor air quality. Choosing these carpets supports sustainable practices and reduces the carbon footprint associated with synthetic materials.

How Does Carpet Density Influence Its Insulating Properties?

The density of carpet significantly affects its insulating properties, particularly in terms of thermal insulation and sound absorption.

- Material Composition: The type of fibers used in the carpet impacts its density, which in turn affects insulation. Natural fibers like wool typically have a higher density and better insulating properties compared to synthetic fibers, making them ideal for thermal insulation in colder climates.

- Pile Height: Carpets with a higher pile height can trap more air, which enhances their insulation capabilities. A plush carpet can create a buffer against temperature fluctuations, providing warmth during winter months and coolness in summer.

- Weight: Heavier carpets generally have greater density, which contributes to better sound insulation. This weight helps to dampen noise transmission, making a carpet not only a good thermal insulator but also an effective acoustic barrier.

- Backing Material: The type of backing used in carpet construction can influence its overall density and insulation properties. A thicker, denser backing can provide additional insulation against heat loss and help maintain a comfortable environment indoors.

- Manufacturing Process: How a carpet is manufactured can determine its density and, therefore, its insulation effectiveness. Techniques that enhance density, such as tufting or weaving tightly, result in carpets that offer superior thermal and sound insulation compared to loosely constructed alternatives.

What Benefits Do Insulated Carpets Provide Beyond Energy Efficiency?

Insulated carpets offer a variety of benefits beyond just energy efficiency.

- Improved Comfort: Insulated carpets provide a soft and cushioned surface underfoot, enhancing the overall comfort of a room. They can retain warmth, making spaces feel cozier, especially during colder months.

- Noise Reduction: The dense fibers of insulated carpets help absorb sound, reducing noise levels within a home. This is particularly beneficial in multi-story buildings or homes with children and pets, as it minimizes the transmission of footsteps or other sounds between rooms.

- Enhanced Indoor Air Quality: Many insulated carpets are made from materials that can trap dust and allergens, preventing them from circulating in the air. This can lead to a healthier living environment, particularly for individuals with allergies or respiratory issues.

- Durability and Longevity: Insulated carpets are often designed to withstand heavy foot traffic while maintaining their appearance over time. This durability can lead to longer-lasting floors, reducing the need for frequent replacements.

- Design Versatility: Insulated carpets come in a wide range of colors, patterns, and textures, allowing homeowners to choose options that match their decor. This aesthetic versatility makes it easy to enhance the visual appeal of any room.

- Moisture Resistance: Some insulated carpets are treated to resist moisture, which can prevent mold and mildew growth. This is particularly important in areas prone to humidity, ensuring that the carpet remains fresh and hygienic.

What Maintenance Tips Can Help Optimize Carpet Insulation Performance?

To optimize carpet insulation performance, consider the following maintenance tips:

- Regular Vacuuming: Frequent vacuuming helps remove dirt and debris that can settle into the carpet fibers, reducing their insulating properties. By keeping the carpet clean, you maintain its ability to trap air and provide thermal resistance.

- Professional Cleaning: Periodic professional cleaning can rejuvenate the carpet fibers and restore their insulating qualities. Cleaning removes deep-seated dirt and allergens, which can hinder the carpet’s performance and longevity.

- Moisture Control: Controlling moisture levels in the home prevents mold and mildew growth, which can damage carpet insulation. Using dehumidifiers or ensuring proper ventilation helps maintain a dry environment, preserving the integrity of the carpet.

- Use of Rugs and Mats: Placing rugs or mats in high-traffic areas can protect the main carpet from wear and tear. This strategy not only extends the life of the carpet but also maintains its insulation effectiveness by preventing compression of the fibers.

- Prompt Stain Treatment: Addressing spills and stains quickly prevents them from setting and damaging the carpet fibers, which can affect insulation. Using the right cleaning products ensures that the carpet remains in optimal condition for insulation performance.

- Temperature Regulation: Keeping the home at a consistent temperature reduces the stress on carpet fibers and helps maintain their insulating properties. Fluctuating temperatures can lead to contraction and expansion of fibers, potentially diminishing their effectiveness over time.